We want you to be completely satisfied with your purchase. If for any reason you are not, we are happy to assist with a return or exchange of your purchase.

Simply contact our customer service team and we will guide through the process to ensure smooth and hassle-free experience.

Customer Service Department on 1800 33 88 88

Email: [email protected]

See our Return Policy.

Mosquito Traps

Mosquito Traps

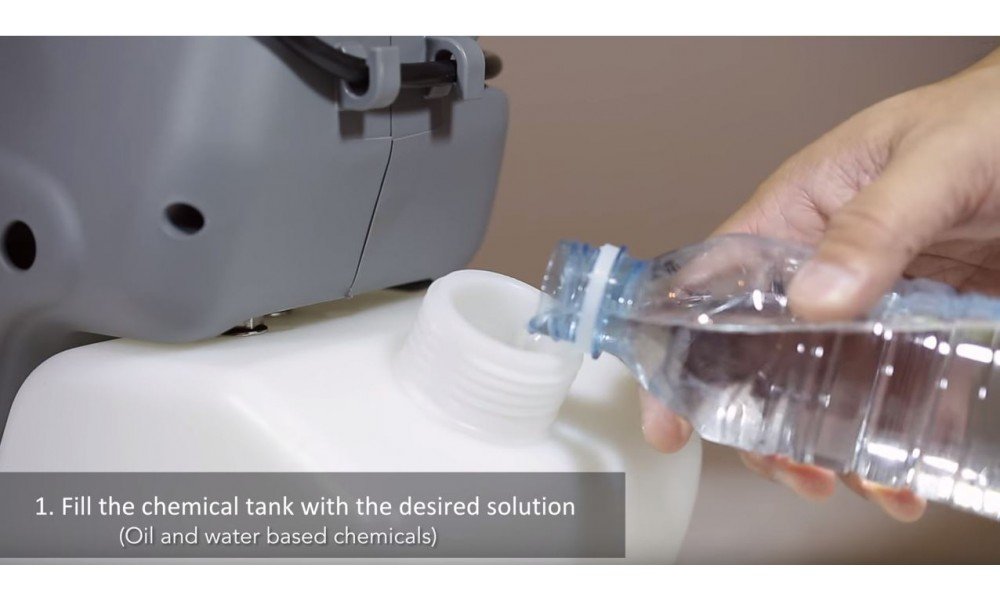

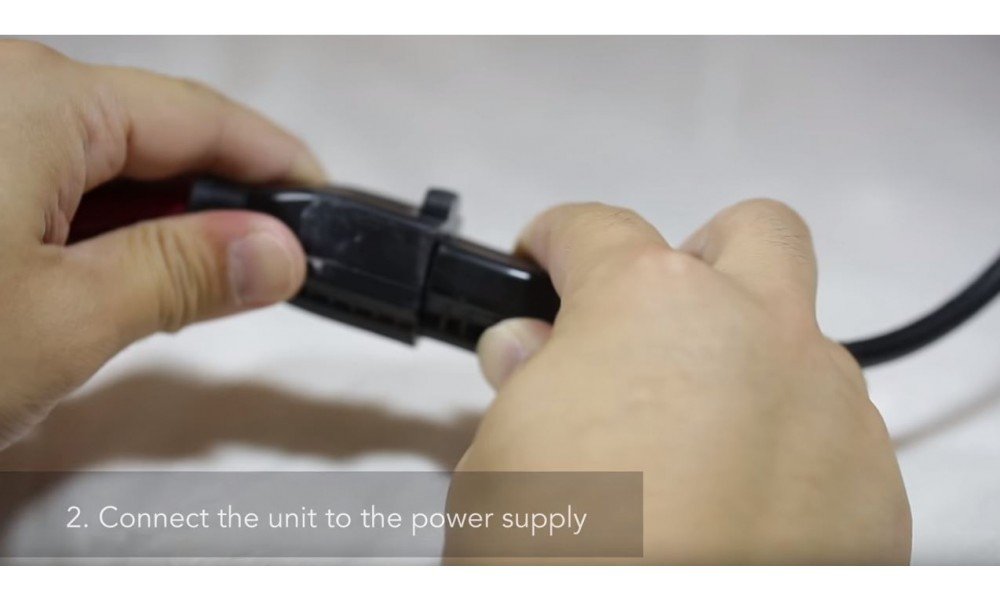

Found the fogger to be very well built and does the job of fogging insecticide very well.